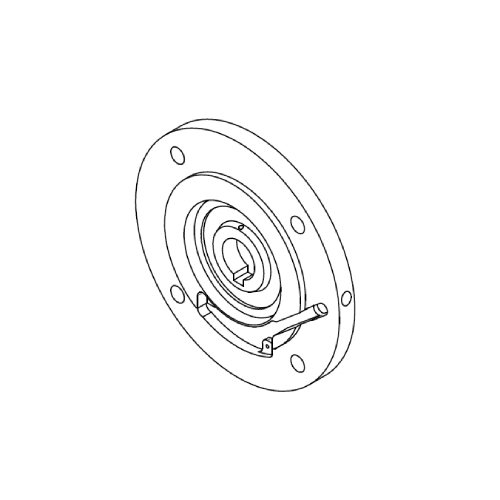

Flange Encoders

The motor does not have to be adapted thanks to this modular design, and this translates into short delivery times and low costs.

The flange, with its fully resin encapsulated electronics, is mounted between the drive unit and the IEC motor. This ensures that it’s completely protected against influences from outside. In addition, the magnet with a very robust construction is mounted on the shaft. This provides additional operational reliability for brake motor applications among others.

Encoder JRSB-serie

> Developed and produced in the Netherlands

> IEC compatible, customization possible

> 1 – 60 pulses per rotation, Channel A and B

> 10 – 24V DC optional 5V DC

> Protectiongrade IP67

> Standard 0,75m cable with ferrules

> Aluminum, Stainless steel

Joint flange encoders according to IEC

In speed controlled applications where a constant RPM or position information is necessary, the JRSB series encoder provides the solution. The encoder flange is designed by IEC standard, and thereby easily installed between the IEC motor and gear unit. There is no need for custom made parts which is in common by comparable encoders.

The pulses are generated by the magnet, and the electronics are fully encapsulated in Epoxy resin. This ensures that the encoder is completely protected against influences from outside. Standard the encoder is supplied with a 0.75 meter encapsulated cable and ferrules. On customer request we can edit the length of the cable and supply it with M8 or M12 connector.

Specifications

Size: IEC 63 – 160 (optional Stainless)

Flange: B14a en B5

Pulses: per rotation 60, 30, 15, 10, 6, 5, 3, 2, 1(optional 1024)

Channel: A and B

Supply voltage Cable: 10-30V DC (optional 5V DC) / 0.75 m, ferrules (optional M8, M12)